How Does It Work?

In the aerospace and marine industries, components are exposed to harsh environments—salt, chemicals, extreme temperatures, and mechanical stress. Surface contaminants such as oxidation, paint, grease, carbon buildup, and corrosion can reduce performance and compromise safety.

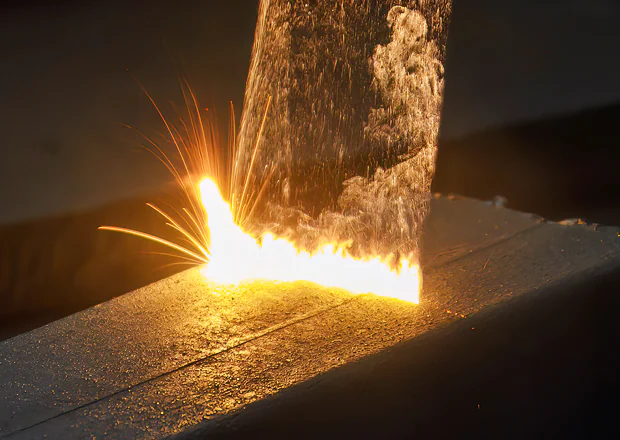

Laser cleaning offers a high-precision, non-contact method for removing these contaminants from metal, composite, and coated surfaces. It works by directing short, intense pulses of laser energy at the surface, vaporizing only the unwanted material without damaging or altering the substrate. This level of precision is essential for mission-critical components in aircraft, spacecraft, and marine vessels. Discover expert aerospace and marine surface solutions with Laser Paint Removal.

What Are the Benefits?

1. Surface Integrity Preservation

No abrasion or distortion—ideal for aluminum, titanium, stainless steel, composites, and sensitive alloys.

2. Ideal for Pre-Coating & Bonding

Cleans surfaces before applying protective coatings, adhesives, or sealants—improving adhesion and durability.

3. Non-Destructive & Repeatable

Perfect for maintenance cycles; no tool wear or repeatability issues compared to mechanical cleaning methods.

4. Environmentally Safe

No chemicals, blasting media, or solvent use—reduces environmental impact and increases workplace safety.

5. Precise & Automated

Laser systems can be handheld for small components or automated for large surface areas, such as fuselages or ship hulls.

Industries

Aerospace Maintenance & Overhaul (MRO) – Cleaning engine components, turbine blades, and landing gear assemblies.

Shipbuilding & Repair – Removing rust, marine growth, and coatings from decks, hulls, and fixtures.

Defense & Military Operations – Maintaining aircraft, naval vessels, and weapon systems with minimal downtime.

Space Industry – Preparing and cleaning high-spec surfaces on satellites and launch equipment.

Aviation Manufacturing – Pre-treatment for painting, bonding, and inspection processes.

Ready to discuss your project? Contact us today for personalized support.

Frequently Asked Questions (FAQs)

Q: Is laser cleaning approved for aerospace-grade materials?

A: Yes. It is used worldwide on aircraft components due to its precision and non-damaging properties. It meets many industry and OEM standards.

Q: Can it be used on composite or carbon fiber parts?

A: Yes, with the correct settings, laser cleaning can safely remove coatings or contaminants from composites without delamination.

Q: How does it compare to sandblasting or chemical stripping?

A: Laser cleaning is cleaner, safer, and more precise—leaving no residue and eliminating the risk of surface pitting or contamination.

Q: Is laser cleaning effective for marine corrosion removal?

A: Absolutely. It’s highly effective at removing rust, scale, and marine buildup without damaging the base metal.

Q: Can it be integrated into automated manufacturing or maintenance lines?

A: Yes. Laser cleaning systems can be integrated into robotic arms or CNC systems for consistent, programmable results.